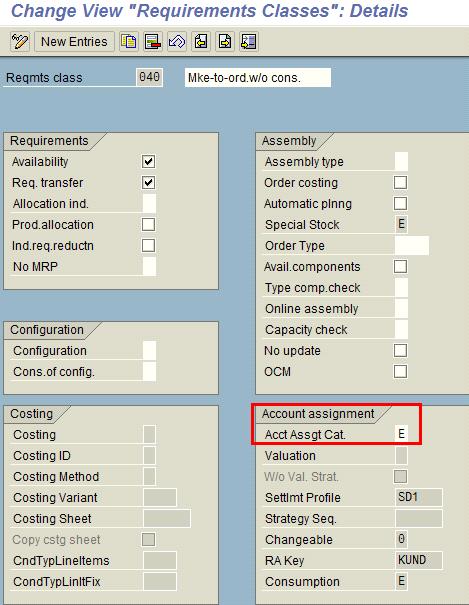

In our case, we have a make to order scenario-20, where by default, the account assignment for planned orders is "E". i.e. sales order.

---

Normally this account assignment flows from Account assignment category defined in the Requirement Class. This Requirement class then assigned to Requirement type. This Requirement type is assigned to Strategy and this Strategy assigned Strategy group. Finally this strategy group is then linked to your material master.

For your case, I think this is coming from the Strategy Group 20.

Check this by the following path:

1. Check the strategy assigned to strategy group 20 in T code OPPT or by path IMG -> Production -> Production Planning -> Demand Management -> Planned Independent Requirements -> Planning Strategy -> Define Strategy Group.

2. Then check which Requirement type is assigned to that Strategy in T Code OPPS or by path IMG -> Production -> Production Planning -> Demand Management -> Planned Independent Requirements -> Planning Strategy -> Define Strategy.

3. Now if this strategy you are using is 20 that is Make to order, then you will find settings for those Requirement type in Sales. For that you can take help from your SD consultant. Also providing you path for the same as below.

4. Check the assignment of Requirement class to requirement type in T Code OVZH or by path IMG -> Sales and Distribution -> Basic Functions -> Availability Check and Transfer of Requirements -> Transfer of Requirements -> Define Requirements Types.

5. At the end you have to check the settings and assignment of 'Account Assignment Category' for your Requirement Class in T Code OVZG or by path IMG -> Sales and Distribution -> Basic Functions -> Availability Check and Transfer of Requirements -> Transfer of Requirements -> Define Requirements Class.

6. Here check the 'Account Assignment Category' under 'Account Assignment' tab.

Note:

Also, check the settings of Individual/coll. in MRP4 view for Semi-FG and Raw material in Material master.

Normally according to standard settings, it will be blank and you keep it as blank then it will take 'Individual and collective requirements' which means it will take FG's requirement. If You keep it as '1-Individual requirements only' then it will take Individual requirement every time means it will be "E" for every requirement if your FG has "E". And if you don't want to follow the FG's requirement plan then you have to keep it as '2-Collective requirements only'.