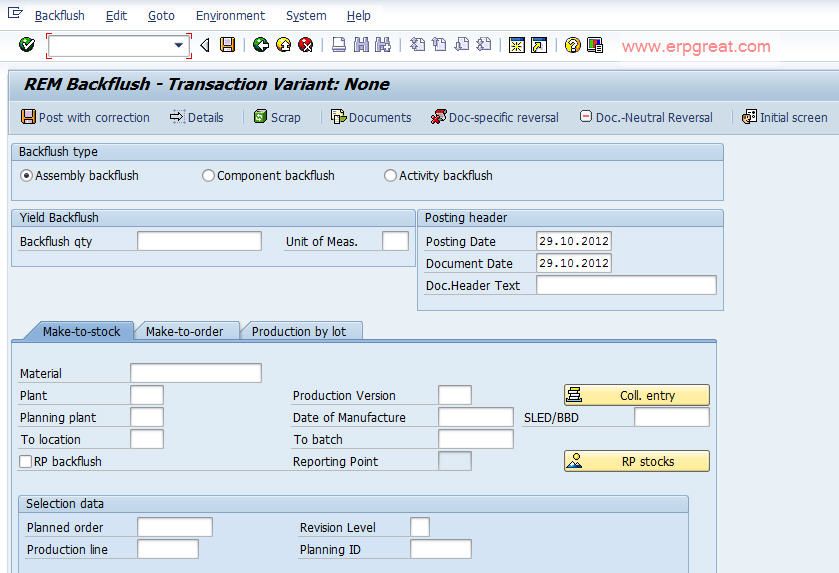

SAP Menu -> Logistics -> Production -> Repetitive Manufacturing - Backflush - REM Backflush

MFBF transaction is related to Repetitive manufacturing production confirmation.

REM is period based production, produced quantities are confirmed by doing backflush (MFBF) at end of shift or day.

Once you do the backflush for Header Material, the following things will happen:

1. Posting GR for finished product, GI for components.

2. Posting production cost for Product cost collector.

Total cost involved in production will be booked for the material.

Like production order confirmation in Discrete Manufacturing, it is a production confirmation process.

The basic configuration steps for REM is as follows:

Master Data Requirement :

1. Define Rem profile - OSP2 and assigned to FG, SFG.

(SPRO settings -> Production -> Repetitive manufacturing -> Control Data -> Define Repetitive Manufacturing Profiles)

2. Define Product cost collector with Production Version in KKF6N

3. Create BOM - CS01

4. Create Rate routing with usage Production and Release

5. Maintain Production version in Material master in MM01 - MRP4

6. Maintain REM material with REM profile active in MRP4 view .

76. Keep material BOM/Routing selection - by Production Version in MRP4

8. Keep the BOM component as BackFlush indicator active in Material Master - MRP3 view

Configuration :

1. Define scheduling parameters for planned orders - OPU5

2. Define and Assign Number Ranges - OSPR

3. Check the operation Control key with reporting point Back Flush - Define Control Key - OP00