The following customizing settings have been done.

1) Control in insp. lot : Manual & automatic data transfer

2) Control in RR: Manual & automatic data transfer

3) Origin TL:04 (Previous inspection point)

4) Data origin RR: 04 (Previous inspection point)

5) Selection: 300 (Custom Selection of inspection lot)

6) Mapping: 200 (master insp. char. & method)

For first inspection point, I am entering results manually. When copying results for second inspection point, system first pop up window for inspection point identifier comes & after that pop up asking for inspection lot comes. After entering lot number system takes to first inspection point only. It does not create new inspection point. What setting are missing or where had gone wrong.

---

Please make sure that you have the following settings:

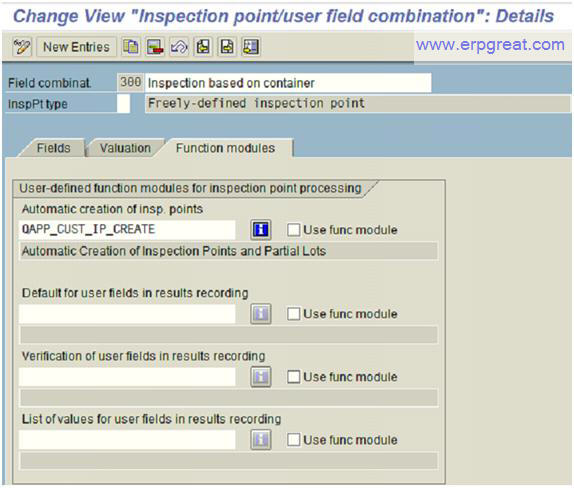

1) In the inspection point you are using, make sure that you have Function module assigned to it in the config.

QCC0 -> Quality Planning -> Inspection Planning -> General -> Define Identifier for Inspection Points -> Inspection point -> Detail -> Function Module QAPP_CUST_IP_CREATE

Sample Screen:

2) In the general view of the characteristic you have maintained origin of Data as 04 previous inspection point.

1) First run the cycle without giving the time factor. Make sure that the copying function is working properly.

2) The reason for inspection point not getting created is based on the production order creation schedule start time and finish time.

The Inspection point generation depends on the scheduled start Date/ Time and finish time.

Make sure that there is considerable time between start to finish so that the inspection point generation time is available.

The starting point (date and time) for processing the operation is defined in the order operation based on the scheduling for the order.

To determine the first inspection point (inspection date), the interval between two inspection points is added to the start date. To do this, the available capacity for the underlying work center is considered.

An inspection point is created for the calculated time, in which the fields "Date" and "Time" (inspection point identification) have entries.

The system continues adding on time until the finish date for "processing" (= start date "Tear down") has been reached.

Therefore, inspection points are created from the start date, after each inspection interval until the end of "processing".

An example given is:

An hour is maintained as the interval for the inspection points in an operation for the routing.

The scheduling for the order means that processing begins on Friday, 08/11/10 at 08.00 and ends on Monday 11/11/10 at 10.00.

The available capacity for the work center shows that the work center is available from Monday to Friday 08.00 - 16.00 (compared to the available capacity for the work center or factory calendar).

The following inspection points are created: (* = Inspection point):

Friday, 08.12

8.00 9.00 10.00 ... 16.00 17.00 ...