Functionality of Quality Inspection

Quality inspection covers the following important functions:

- Inspection lot creation

In the QM component, you process quality inspections on the basis of inspection lots. If you want to inspect a specific quantity of a material or a piece of equipment, an inspection lot must be created in the system. Once an inspection lot has been created, you can inspect the goods, record the inspection results or defects, and complete the inspection with a usage decision.

- Results recording

Here, you record and process results for inspection characteristics. The inspection lot is the reference object in results recording. The recorded inspection results document the quality of the inspected product, and provide the basis for creating batch specifications and inspection certificates. You can use the recorded result data to make evaluations for quality control purposes.

- Defects recording

When you process an inspection lot, you can record the results for the inspection in the form of characteristic values or defects. A defect is any property or attribute of a material, product or process that does not meet the inspection characteristic specifications. You record the defects with the help of predefined defect codes maintained in the inspection catalogs.

- Inspection lot completion

After the results have been recorded for an inspection lot and the inspection is finished, you must reach a decision about the usage of the inspected material. With the Inspection Lot Completion component, you set the controls that:

- Complete an inspection (inspection lot completion).

- Make the usage decision for the inspection lot.

- Make the usage decision for every individual operation in an inspection lot (for more information, see Completing the Operations in an Inspection Lot).

- Perform stock postings for inspection lots created on the basis of goods movements (for example, to unrestricted-use stock, blocked stock, scrap)

When you make a usage decision for an inspection lot, the following occur automatically:

- A quality score is determined for the inspection lot.

- The quality level (inspection stages for the next inspection lot) is updated.

- The quality management information system is updated with statistical data.

- Automatic follow-up actions are triggered.

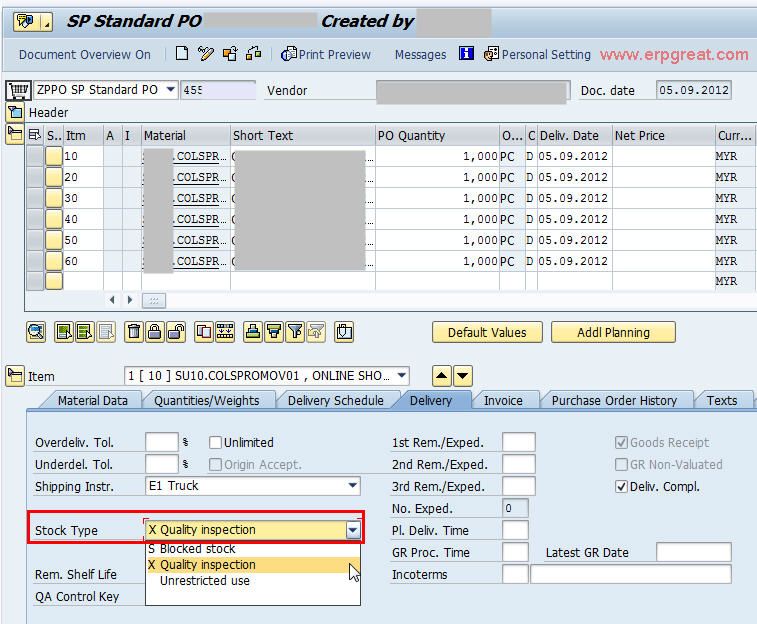

Quality Inspection Indicator in The Purchase Order Item

Is there any specific indicator for "Quality inspection" in Purchase Order Item OR just we need to select Stock Type (Quality Inspection ) if item is subject to Quality inspection (without inspection lot processing / Stock relevant inspection)?

There are two ways by which the material goes to Quality.

One if QM is active (i.e. processing of Inspection lots etc.).

The other is in Material master. There are two places, one in Purchasing view and the other in QM view.

In Purchasing view, we have to select Stock type "Quality inspection" at PO item detail. When we maintain QM for this material then it get subjected to Quality inspection. At Material Master record, in purchasing view, flag the indicator for "Post to inspection stock" which always subjects this material to QI.

For set up in Quality view ,there is a check mark which says "post to Inspection stock ". Please check this indicator and the material will default to Quality during GR. This indicator is checked without going into Inspection setup.